The long-talked-about Nambour Tram has moved a step closer to fruition with the delivery of two purpose-designed and built bogies.

The Nambour Tramway Company chairman Greg Rogerson said it was satisfying for the project team to possess physical tram pieces for the first time in the project’s 13-year history.

“The day that they came in, it wasn’t just talk anymore,” Mr Rogerson said.

He said it was encouraging for all involved to see the results of their work.

“All the design work, all the angst and all the keeping up with the Office of the National Rail Safety Regulator (ONRSR) mandatory details and so forth, to see the bogies completed is sensational and I genuinely think that when we put the chassis and superstructure on top of the bogies, you’ll see another gigantic change.

“It will demonstrate to the community that’s waited a long, long time that this is going to happen, that this tram will be the best tram of its kind in the world, and even more amazing is the fact that it will be running through the very heart of Nambour.”

For more local news videos SUBSCRIBE to our YouTube channel. Just click here.

The 1.5-tonne, four-wheeled bogies are the structures upon which the tram chassis and superstructure will sit.

Worth about $35,000 each, they were built by Bradken Civil in Ipswich and Innisfail, and delivered to the TNTCo terminal at Nambour by Clayton’s Towing.

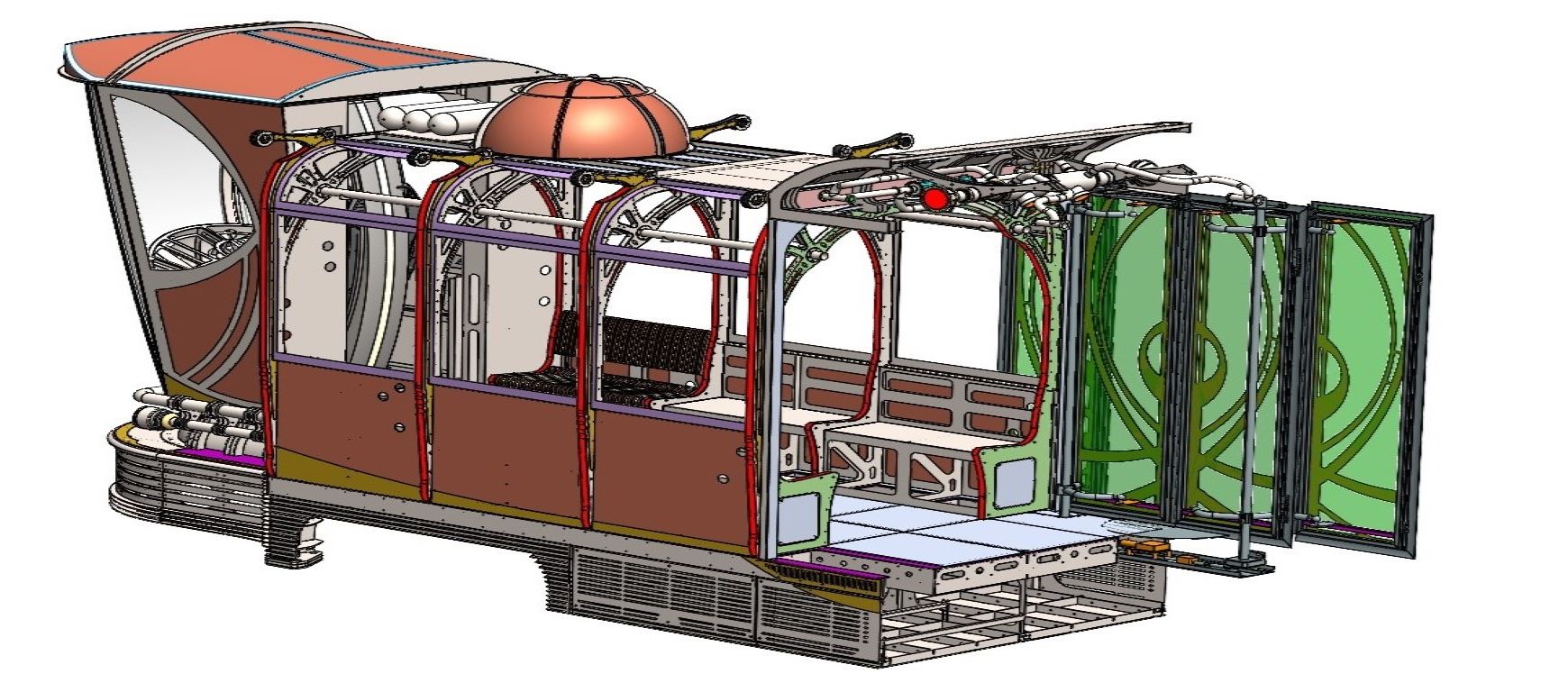

Mr Rogerson said the chassis and superstructure were now undergoing final FEA (finite element analysis) and engineering in a collaboration between Russell Anderson of Art Plus Design, Covey Associates and Australian firm LEAP, agents for world’s best-practice FEA software ANSYS.

Do you have an opinion to share? Submit a Letter to the Editor at Sunshine Coast News via news@sunshinecoastnews.com.au. You must include your name and suburb.

LEAP Australia has carried out similar work for the Bushmaster personnel vehicles used by the Australian Army and the foiling boats used by Emirates Team New Zealand in the latest America’s Cup campaign.

Following FEA, the chassis design will go through three levels of engineering sign-off and final sign-off by the TNTCo board before construction can begin.

After the chassis and superstructure have been cut, welded, bead blasted and painted, Mr Anderson will start building the steampunk-inspired tram.

It will initially run along 800m of heritage-listed cane train lines from the Western Terminus into Howard Street and back, but stage two of the project will extend the run to the showgrounds and back.

The tram project has attracted some criticism from sceptics and people who do not see it as meaningful public transport.

Mr Rogerson said the arrival of the bogies was proof that the tram was definitely happening.

The bogies will be available for public viewing at the Christmas Tramfest this Saturday from 4-9pm.

Bogie talk

- Each bogie has four chrome molly wheels: two on the driving axle and two on the lazy axle.

- Both bogies will be powered by 48-volt AC brushless motors, wound and supplied by Newcastle firm Catavolt, and that will and drive power through an industrial/commercial German SEW transmission on each bogie.

- Each bogie will have three brake mechanisms: a manually operated brake that actuates on the electric motor armature shaft; a spring-actuated, hydraulic released disc brake, mounted in the centre of the lazy axle on each bogie; and regenerative braking, which is applied to the tram via the electric motors converting the generated kinetic energy of the moving tram, back to electrical energy.

- This energy will be applied and fed through two Curtis controllers (one in each driver compartment) for storage in 32 super-capacitors, which will be used to power the tram, which will have no batteries.

- The tram will be charged every four to six trips using the 32.4kWs of solar panels on the roof of the Western Terminus. Each charge will take about 15 minutes.