A leading Sunshine Coast manufacturer that specialises in helicopter modifications is ready to take its capabilities to another level.

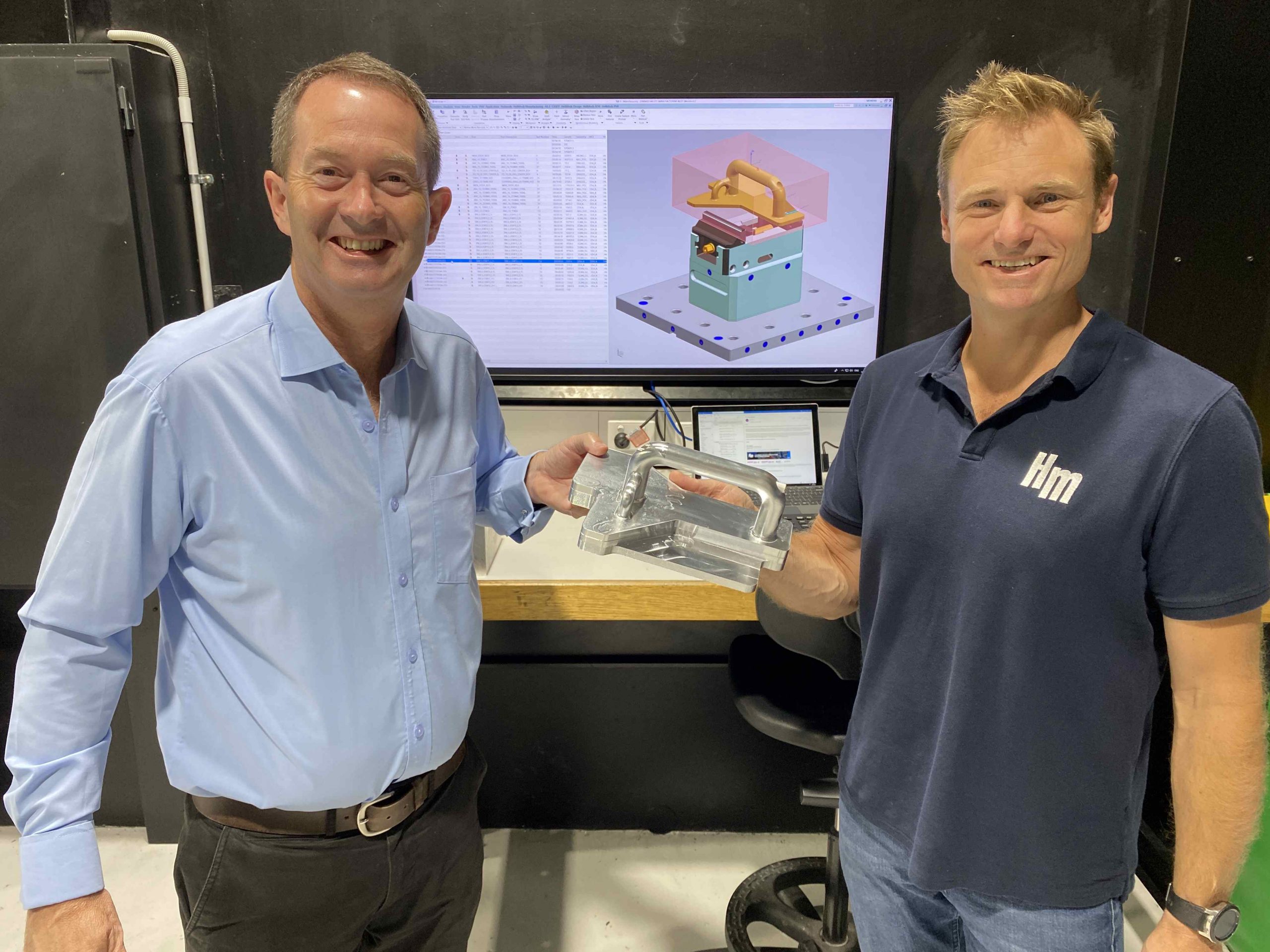

Caloundra-based HeliMods boasts world-class abilities to customise aircraft – including design, engineering, manufacturing, certification and systems integration.

The company, founded in 2002, is able to transform standard factory aircraft into machines that are capable of performing special missions, including tactical operations, aerial policing, emergency medical services and search and rescue operations.

They service the Australian Defence Force and LifeFlight Australia and also have international clients from as far afield as Canada.

Now, the company is set to improve its product design and manufacturing process with a digital upgrade, thanks to a Federal Government co-investment grant of $350,000.

The grant supports the company’s implementation of Closed Loop Manufacturing (re-using production materials to reduce costs and improve quality), with cutting-edge software known as the Manufacturing Execution System (tracks and documents the transformation of raw materials to finished goods).

Federal Member for Fisher Andrew Wallace said the upgrade was supported by funding through the Government’s Advanced Manufacturing Growth Centre.

“To create the vibrant and successful Sunshine Coast we all want to see as we build our recovery from COVID-19, I believe we need to diversify our local economy,” he said.

“I know that advanced manufacturing leaders like HeliMods share that vision for our region and I’m certain that they will be at the forefront of creating the jobs of the future we need.

“I am delighted to see the Federal Government stepping up to help make the Sunshine Coast the hi-tech manufacturing hub we know it can be.”

The Advanced Manufacturing Growth Centre was established in 2015 and its goal is to drive innovation, productivity and competitiveness across Australia’s manufacturing industry.

AMGC is an industry-led, not-for-profit organisation and is run by a board and management team of industry experts.

“Thanks to this project, HeliMods is now the only Australian business with Defence Production Approval that is using such a Closed Loop Manufacturing system, offering Australia a unique new sovereign defence industry capability based right here on the Coast,” Mr Wallace said.

“HeliMods, with the support of the Federal Government, Siemens and AMGC is leading the way not only in growing our local economy, but in delivering the cutting-edge tools our serving men and women need.”

The Siemens MES solution will allow HeliMods to develop and manufacture complex and high-value products quickly and efficiently, using a single digital solution across the entire process.

This will help HeliMods to become stronger and more competitive in the global marketplace, opening new export opportunities with customers in European and North American markets.

HeliMods Founder and Managing Director Will Shrapnel said the business could expand its reach.

“With these digital tools we can take our innovations to the world,” he said.

“As we grow in strength and market scope, it is critical to leverage the hi-tech manufacturing technology that enables highly-streamlined work, freeing up our talent to focus more on product innovation.”

The new system will enable HeliMods to connect to manufacturing infrastructure anywhere in the world and increases transparency for high security industries including defence.

Siemens Australia’s Chairman and CEO Jeff Connolly congratulated HeliMods on their growth and recent implementation.

“HeliMods is a great example of Australian ingenuity and innovation that has flourished using digital technologies,” he said.

Help keep independent and fair news coming by subscribing to our free daily news feed. All it requires is your name and email. See SUBSCRIBE at the top of this article.

In addition to $350,000 from the AMGC, the project is supported by a $428,543 contribution from HeliMods and a $30,000 in-kind contribution.

“The Morrison Government is committed to making Australia a high quality, sustainable manufacturing nation through our $1.5 billion Modern Manufacturing Strategy,” Mr Wallace said.

“Locally, that means supporting Sunshine Coast experts like HeliMods to collaborate with and compete alongside some of the world’s biggest companies with projects like this and I am excited to see what’s next for Will and his team.”